The air brake warning switch is a critical safety component in vehicles equipped with air brake systems. It acts as a sentinel, alerting the driver to potential issues that could compromise braking performance. This article dives deep into the air brake warning switch, covering its function, common problems, diagnostic procedures, and solutions.

After the introduction, you can explore more about the specific brake pressure warning switch in air brake pressure warning switch.

How Does an Air Brake Warning Switch Work?

The air brake warning switch is designed to monitor air pressure within the braking system. When the air pressure drops below a predetermined threshold, the switch activates, triggering a visual or audible warning signal to alert the driver. This prompt notification allows the driver to take corrective action, preventing potentially dangerous situations. The switch typically consists of a diaphragm or pressure sensor that reacts to changes in air pressure. When pressure drops, the diaphragm or sensor moves, closing an electrical circuit and activating the warning system.

Common Problems with Air Brake Warning Switches

Several issues can affect the air brake warning switch, leading to malfunction. These include:

- Faulty Switch: The switch itself can fail due to internal component damage, corrosion, or wear and tear.

- Wiring Problems: Damaged, corroded, or loose wiring connections can disrupt the switch’s operation.

- Low Air Pressure: While not a switch problem itself, consistently low air pressure can trigger the warning light and indicate a leak or compressor issue.

- Malfunctioning Pressure Sensor: If the vehicle utilizes a pressure sensor instead of a diaphragm, a faulty sensor can provide inaccurate readings, leading to false warnings or a failure to warn.

Diagnosing Air Brake Warning Switch Problems

Troubleshooting an air brake warning switch involves several steps:

- Check the Air Pressure: Verify that the air pressure in the system is within the recommended range. If it’s low, address the underlying air leak or compressor issue.

- Inspect the Wiring: Examine the wiring connected to the switch for any signs of damage, corrosion, or loose connections. Repair or replace any faulty wiring.

- Test the Switch: Use a multimeter to test the switch’s continuity. With the air pressure below the threshold, the switch should close the circuit. If it doesn’t, the switch is likely faulty and needs replacement.

- Diagnose the Pressure Sensor (if applicable): If the system uses a pressure sensor, specialized diagnostic tools may be needed to verify its accuracy. Consult a qualified technician if necessary.

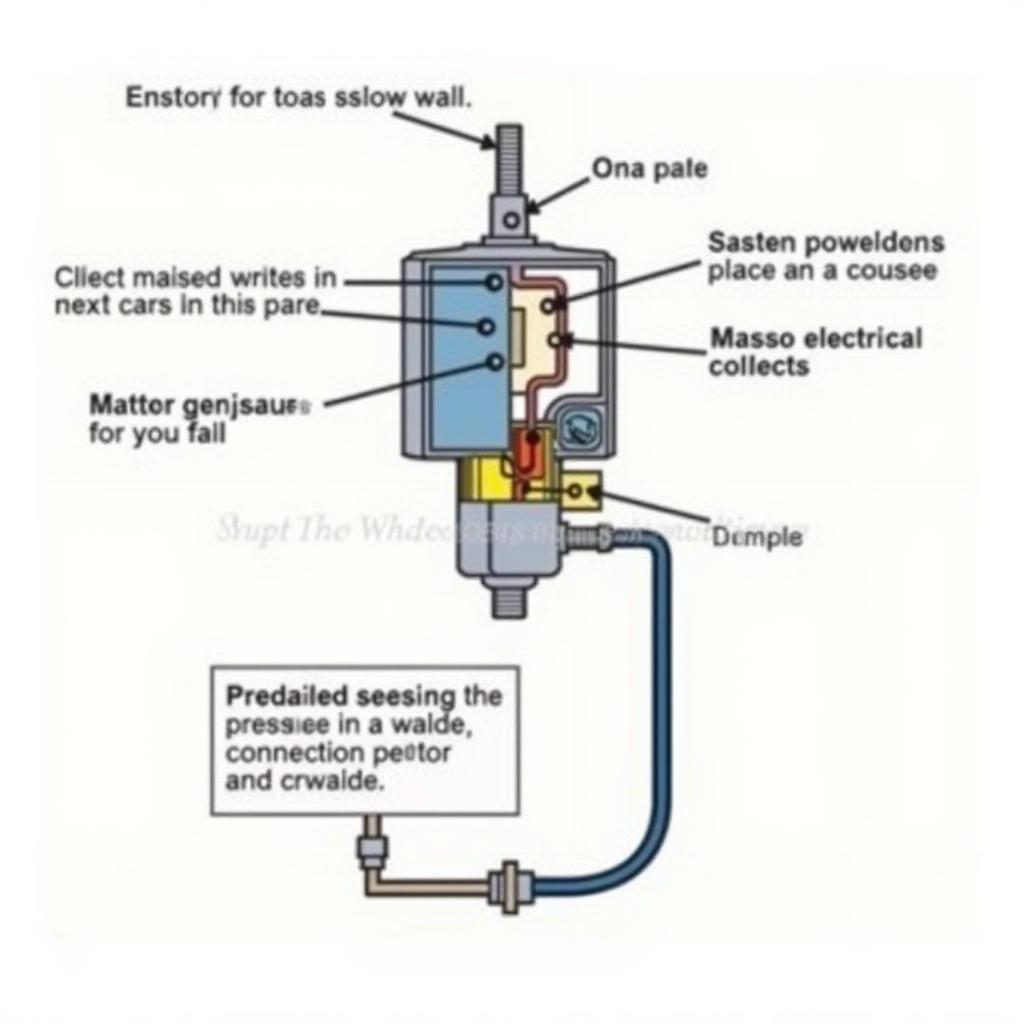

Air Brake Warning Switch Diagram

Air Brake Warning Switch Diagram

Replacing the Air Brake Warning Switch

Replacing the air brake warning switch is usually a straightforward process.

- Locate the Switch: The switch is typically located in the air brake system’s primary air tank or near the brake valve.

- Disconnect the Wiring: Carefully disconnect the electrical connector from the switch.

- Remove the Switch: Unscrew the switch from its mounting location.

- Install the New Switch: Screw the new switch into place and reconnect the wiring.

- Test the System: Check the air pressure and ensure the warning light functions correctly.

This process might be similar to replacing a park brake warning switch, which you can find in 1997 nissan d21 park brake warning switch.

Preventing Air Brake Warning Switch Problems

Regular maintenance can help prevent air brake warning switch issues. This includes:

- Checking Air Pressure Regularly: Monitor the air pressure and address any leaks promptly.

- Inspecting Wiring and Connections: Periodically inspect the wiring for damage or corrosion.

- Draining Air Tanks: Regularly drain the air tanks to remove moisture and contaminants that can contribute to corrosion.

For certain vehicles, the brake master cylinder warning switch might play a similar role. You can learn more about it through 1988 corvette brake master cylinder warning switch.

Conclusion

The air brake warning switch is a vital component for safe vehicle operation. Understanding its function, common problems, and diagnostic procedures empowers drivers and technicians to maintain a reliable braking system. By following the outlined preventive measures and addressing issues promptly, you can ensure optimal braking performance and enhance safety on the road. Don’t ignore the air brake warning light – it’s there to protect you.

You might also be interested in learning about a specific case on brake warning light switch in 1977 chryrsler newyorker brake warning light switch. Also, you can find more information on brake pressure warning switch specifically for Cadillac EXT at 2002 cadillac ext brake pressure warning switch.