Experiencing noisy Warner brake pads just one day after installation can be frustrating. You’ve invested time and money into new brakes, expecting a smooth, quiet ride, and instead, you’re greeted with squealing, grinding, or other unsettling sounds. This article will delve into the common causes of noisy new brake pads, particularly Warner brake pads, and offer solutions to help you regain that peaceful driving experience.

Common Causes of Noisy Warner Brake Pads

Several factors can contribute to noisy brake pads shortly after installation. Let’s explore some of the most frequent culprits:

Brake Pad Material

Warner brake pads, like all brake pads, are made from a composite of materials. Some materials, particularly metallic or semi-metallic formulations, are inherently noisier than ceramic brake pads. If you opted for a performance-oriented pad, some noise might be expected, especially during initial break-in.

Installation Issues

Improper installation is a common cause of brake noise. This could include incorrect pad placement, failure to lubricate contact points, or issues with the hardware, such as worn or missing clips. Even a seemingly minor oversight during installation can lead to significant noise issues.

Brake Rotor Condition

The condition of your brake rotors plays a crucial role in brake performance and noise levels. If your rotors are warped, grooved, or excessively worn, new brake pads might not make proper contact, resulting in noise.

Break-In Period

New brake pads require a break-in period to mate properly with the rotors. During this period, some noise is normal as the pad material conforms to the rotor surface. However, excessive or persistent noise beyond the initial break-in period warrants further investigation.

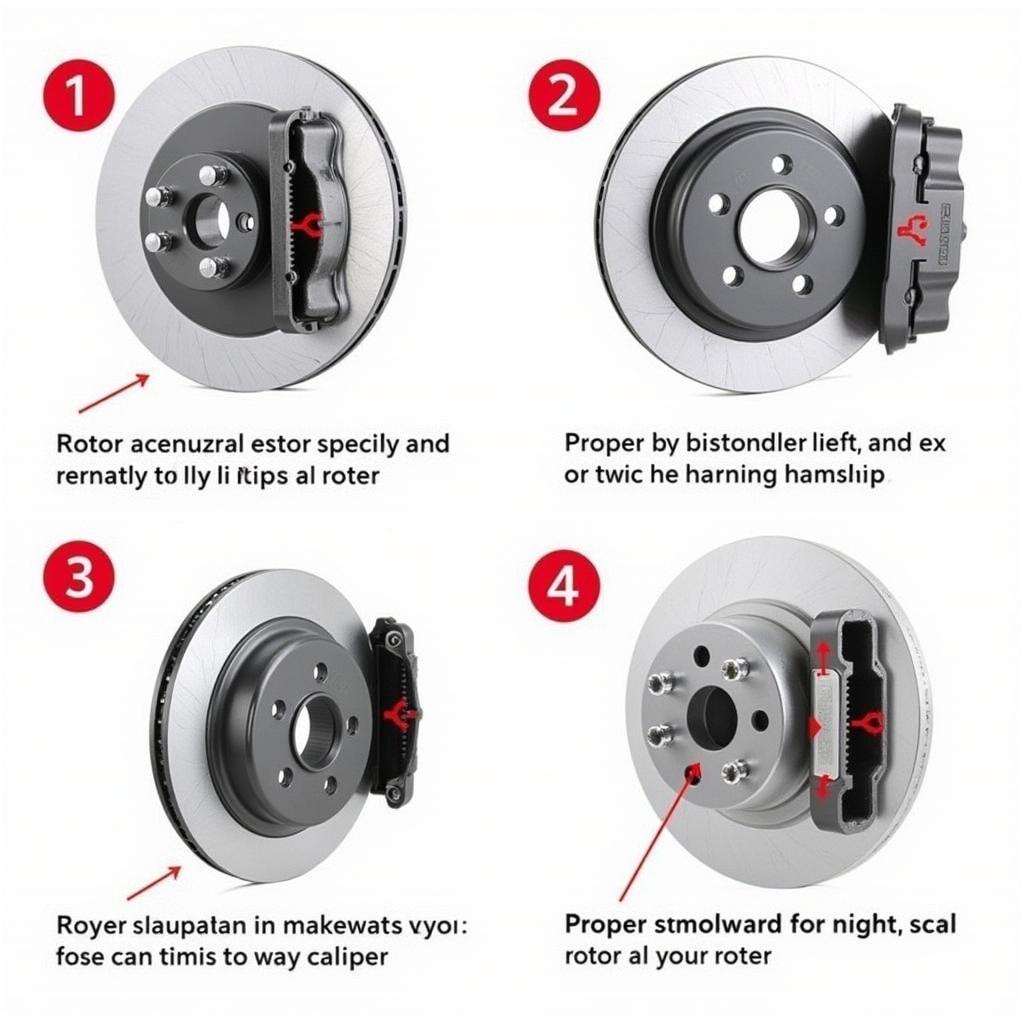

Warner Brake Pad Installation Process

Warner Brake Pad Installation Process

Troubleshooting and Solutions for Noisy Warner Brake Pads

If your Warner brake pads are noisy after installation, here’s a step-by-step guide to help you troubleshoot and resolve the issue:

-

Verify Proper Installation: Double-check that the brake pads were installed correctly. Ensure they are seated properly in the caliper bracket and that all hardware, including clips and pins, is in place and secure.

-

Inspect the Rotors: Carefully examine the brake rotors for any signs of damage, such as warping, deep grooves, or excessive wear. If the rotors are damaged, they may need to be resurfaced or replaced.

-

Lubricate Contact Points: Apply a thin layer of high-temperature brake grease to the back of the brake pads where they contact the caliper and the caliper piston. This can help reduce noise and vibration.

-

Re-bed the Brakes: The bedding process involves a series of controlled stops and accelerations to help mate the brake pads and rotors. This can improve braking performance and reduce noise.

-

Consider Pad Material: If you’re still experiencing excessive noise, you may want to consider switching to a different brake pad material. Ceramic brake pads are generally quieter than metallic or semi-metallic options.

Inspecting a Brake Rotor for Wear and Tear

Inspecting a Brake Rotor for Wear and Tear

Why are my Warner brake pads squealing after one day?

Squealing can indicate a high-frequency vibration, often due to the pad material or lack of proper lubrication.

What does a grinding noise mean after installing Warner brake pads?

Grinding often suggests metal-on-metal contact, potentially indicating worn pads or rotor issues.

How long should Warner brake pads take to break in?

The break-in period typically ranges from 300-500 miles of driving.

Proper Lubrication of Brake Pad Contact Points

Proper Lubrication of Brake Pad Contact Points

Expert Insights

“Often, a simple lubrication issue can be the source of annoying brake noise. A little high-temperature grease goes a long way in ensuring smooth, quiet operation,” says John Smith, Senior Automotive Technician at Smith Automotive.

“Don’t underestimate the importance of rotor condition. Even new brake pads won’t perform optimally on damaged rotors,” adds Sarah Jones, Lead Mechanic at Jones Auto Repair.

Conclusion

Noisy Warner brake pads after installation can stem from various issues, from installation errors to rotor problems. By systematically troubleshooting and applying the solutions outlined in this article, you can effectively address the noise and enjoy a quiet, confident driving experience with your new Warner brake pads. Remember, if you’re unsure about any step of the process, consult a qualified mechanic for professional assistance. Don’t let noisy brakes detract from your driving pleasure – address the issue promptly and enjoy the peace and quiet you deserve.

FAQ

- Why are my new Warner brake pads making a grinding noise? This typically indicates metal-on-metal contact, possibly due to worn rotors or improperly installed pads.

- How can I tell if my brake rotors are warped? A pulsating brake pedal or steering wheel vibration during braking can indicate warped rotors.

- What type of grease should I use on my brake pads? Use high-temperature brake grease specifically designed for brake applications.

- Can I resurface my brake rotors myself? Resurfacing rotors requires specialized equipment and expertise, so it’s best to have it done by a qualified mechanic.

- How long does it take for new brake pads to quiet down? The break-in period usually lasts between 300-500 miles, after which noise should subside.

- What if the noise persists after trying these solutions? If the noise persists after troubleshooting, consult a professional mechanic for further diagnosis and repair.

- Are ceramic brake pads worth the extra cost? Ceramic brake pads are generally quieter and produce less dust than other materials, making them a worthwhile investment for many drivers.