The Warner double c-face brake is a crucial component in various industrial applications, from heavy-duty machinery to automotive systems. Experiencing issues with this type of brake can lead to costly downtime and safety concerns. This guide explores common problems, diagnostic procedures, and the increasing role of remote software solutions in resolving Warner double c-face brake issues.

Understanding the Warner Double C-Face Brake

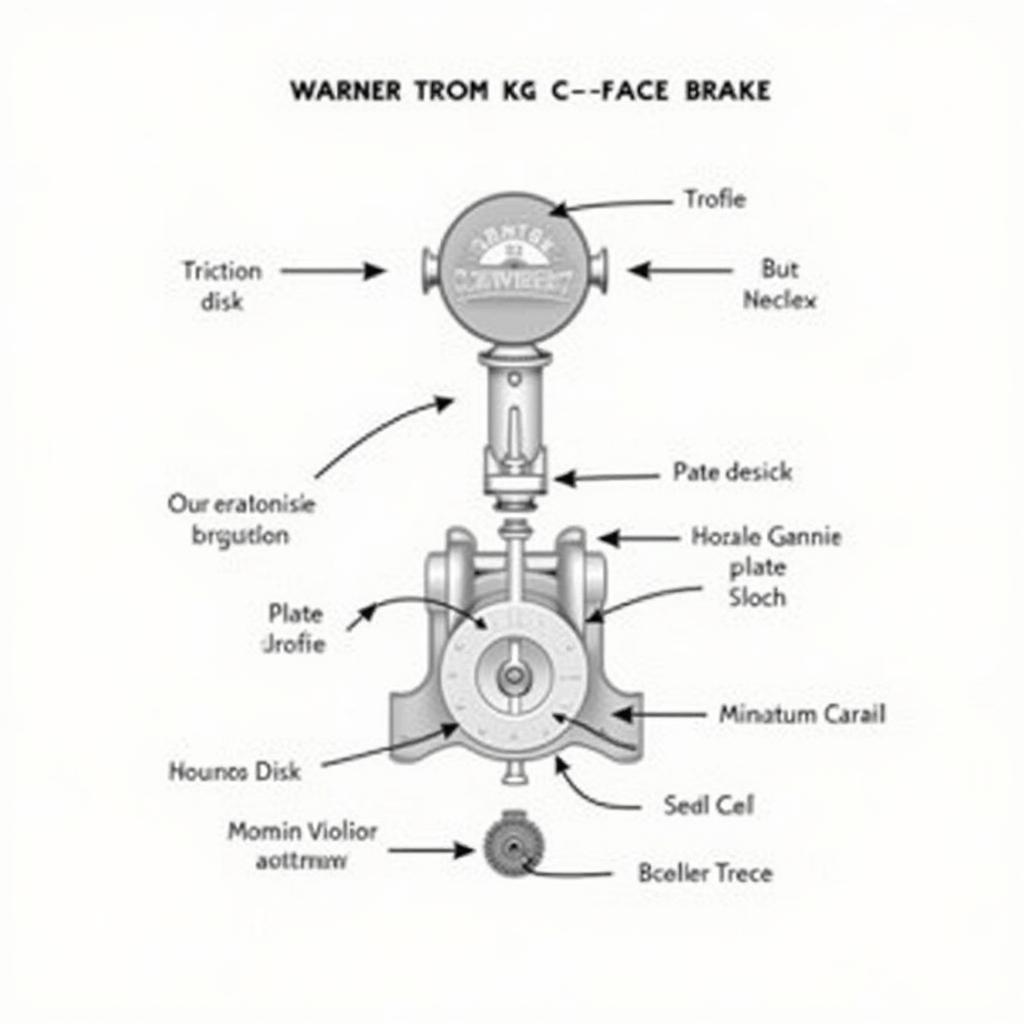

The double c-face mounting configuration provides a robust and versatile solution for connecting brakes to motors and gearboxes. This design allows for easy installation and maintenance. Understanding its operation is key to effective troubleshooting. The brake typically consists of a friction disc, pressure plate, and an actuator, which can be pneumatic, hydraulic, or electric. When the actuator is energized, the pressure plate releases the friction disc, allowing the shaft to rotate. Conversely, when the actuator is de-energized, the pressure plate engages the friction disc, stopping the shaft.

Common Issues with Warner Double C-Face Brakes

Several issues can arise with Warner double c-face brakes, impacting performance and safety. These include:

- Excessive Wear: Friction material wear is a natural occurrence, but premature wear can indicate misalignment, incorrect air gap, or improper operating conditions.

- Overheating: Overheating can be caused by excessive slipping, incorrect brake sizing, or inadequate cooling.

- Sticking or Dragging: This can result from contamination, corrosion, or a malfunctioning actuator.

- Noise: Unusual noises, like squealing or grinding, can point towards worn friction material, loose components, or improper lubrication.

- Air Leaks (for Pneumatic Brakes): Leaks in the air supply system can lead to reduced braking force or complete brake failure.

Warner Double C-Face Brake Components Diagram

Warner Double C-Face Brake Components Diagram

Diagnosing Warner Double C-Face Brake Problems

Diagnosing brake problems requires a systematic approach. Visual inspections are a good starting point, looking for signs of wear, damage, or contamination. Checking the air gap (for pneumatic brakes) is crucial. Furthermore, monitoring operating parameters such as temperature, pressure, and actuation time can provide valuable insights.

Utilizing Remote Diagnostics and Programming

Advances in technology have brought about remote diagnostics and programming, revolutionizing the way we troubleshoot and repair complex systems like the Warner double c-face brake. Specialized software allows technicians to access brake controllers remotely, analyze real-time data, and identify potential issues. This reduces downtime significantly.

Remote Software Solutions: The Future of Brake Repair

Remote software solutions are becoming increasingly prevalent in the automotive and industrial sectors. They enable technicians to:

- Perform Remote Diagnostics: Analyze real-time data and identify issues without physical access to the equipment.

- Implement Software Updates: Update brake control software remotely, improving performance and addressing bugs.

- Adjust Brake Parameters: Fine-tune brake settings for optimal performance and efficiency.

- Monitor Brake Health: Track key performance indicators and predict potential failures.

“Remote diagnostics and programming are game-changers,” says John Smith, Senior Automotive Engineer at Acme Industries. “They allow us to address brake issues quickly and efficiently, minimizing downtime and maximizing productivity.”

Conclusion

Troubleshooting Warner double c-face brakes requires a thorough understanding of their operation and potential issues. Utilizing remote software solutions offers significant advantages in terms of speed, efficiency, and cost-effectiveness. By embracing these technologies, industries can enhance their maintenance strategies and ensure optimal performance of their Warner double c-face brake systems.

FAQ

- What is the most common cause of Warner double c-face brake failure? Excessive wear and overheating are frequent causes.

- How often should I inspect my Warner double c-face brakes? Regular inspections, as per the manufacturer’s recommendations, are essential for preventative maintenance.

- Can I adjust the air gap on my Warner double c-face brake myself? While possible, it’s recommended to consult a qualified technician to ensure proper adjustment.

- What are the benefits of using remote software solutions for brake repair? Reduced downtime, faster diagnostics, and improved maintenance efficiency are key benefits.

- How can I access remote diagnostics software for my Warner double c-face brakes? Contact your brake supplier or a qualified technician for information on available software solutions.

- What are the signs of a failing Warner double c-face brake? Noise, overheating, sticking, dragging, and reduced braking force are potential indicators.

- How can I prevent premature wear on my Warner double c-face brake? Proper installation, regular maintenance, and ensuring correct operating conditions are key to preventing premature wear.